Information

Currently, the production of M100, M110, M110BX has been stopped (they have been replaced with M410RT and M420T automatic machines).

However, they exist on market as used.

We provide spare parts, maintenance materials and service.

|

PUNCHING AND CUTTING

|

||||

|---|---|---|---|---|

| WS-01/16 | Dziurkownik | |||

| WS-01/16/6×2,5/Fix-S | Dziurkownik | |||

| WS-01/25 | Dziurkownik | |||

| WS-01/25/3×6-TP-H | Dziurkownik | |||

| WS-02/25 | Rozcinak | |||

Description

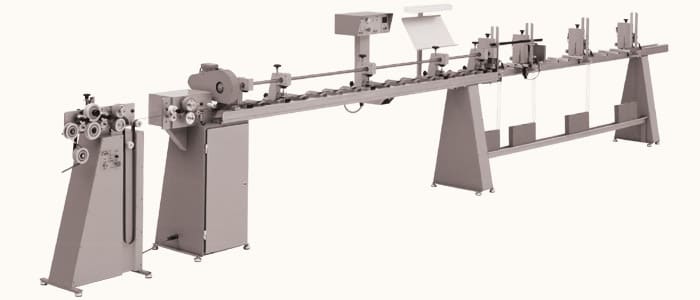

Automatic machine MAGNUM-100 is deisgned for forming, punching of holes and cutting of louver strip to the desired lenght. It also enables assembling of ordered number of louver-blades together with ladder – strings in automatic cycle. In automatic machine MAGNUM-110 is used a central control system of rewinding unit and of the strip feeding rollers (programmer, inverters, electrical slutches). This system maintains in a continous way constant and stable tension of a louver strip and replenishes automatically store of the formed strip.

Technical solutions applied in this machine eliminate all the inertial forces during the rewinding of a louvers strip, which affects distinctly the quality improvement of the louvers blades forming process.

Automatic machine MAGNUM – 110 BX is desinged for production – in automatic cycle – of 1 to 5 louve – blades simultaneously, depending of length of machinery and its equipment.

Automatic machine is equipped with pneumatic shearing units which are set up on the assembilng device.

Assembling units are equipped with some facilities which provide the top storage container with ready made louvers.

Additional equipment

- Set of forming rolls, guides and tools for louver-strip of 16 mm width

- Pneumatic shearing unit – enables to produce two louver strips simultaneously

- Punching units

- Threading units

Dane Techniczne

| M100 | M110 | M110BX | |

|---|---|---|---|

| Szerokość piórka | 16mm lub 25mm | 16mm lub 25mm | 16mm lub 25mm |

| Długość ciętych piórek | 360 – 3000 mm | 360 – 3000 mm | 360 – 3000 mm |

| Liczba stacji dziurkujących | 4 | 4 | 6-12 |

| Liczba stacji rozcinających | 1 | 1 | 1 mechaniczna 1+3 pneumatyczne |

| Liczba stacji składających | 4 | 4 | 6-12 |

| Min. odległość otworu brzegowego od brzegu piórka | 120 mm i 150mm | 120 mm i 150mm | 120 mm i 150mm |

| Max. prędkość podawania taśmy | 0-2,3 m/sek. regulowana bezstopniowo |

0-2,7 m/sek. regulowana bezstopniowo |

0-2,7 m/sek. regulowana bezstopniowo |

| Cykl podawania taśmy | dwubiegowy | dwubiegowy | dwubiegowy |

| Zasilanie | 3×220/380 V, 50Hz | 3×220/380 V, 50Hz | 3×220/380 V, 50Hz |

| Sprężone powietrze | 0,6 MPa | 0,6 MPa | 0,6 MPa |

| Zużycie powietrza | 4 m3/h | 4 m3/h | 5-10 m3/h |

| Waga netto | 320 kg | 420 kg | 440 kg |

.